High-pressure systems require component parts that are reliable and efficient and used under efficient conditions. This includes check, ball, plug, and other high performance butterfly valves among the significant elements in such systems With the many features that accompany the butterfly high performance valves, they have gained a deserved popularity within the industry due to their longevity, efficiency as well as the comparatively cheap costs of acquiring them. This article will address the advantages of selecting high performance butterfly valves for high pressure applications and why qualifying the manufacturer in China is critical.

Guide

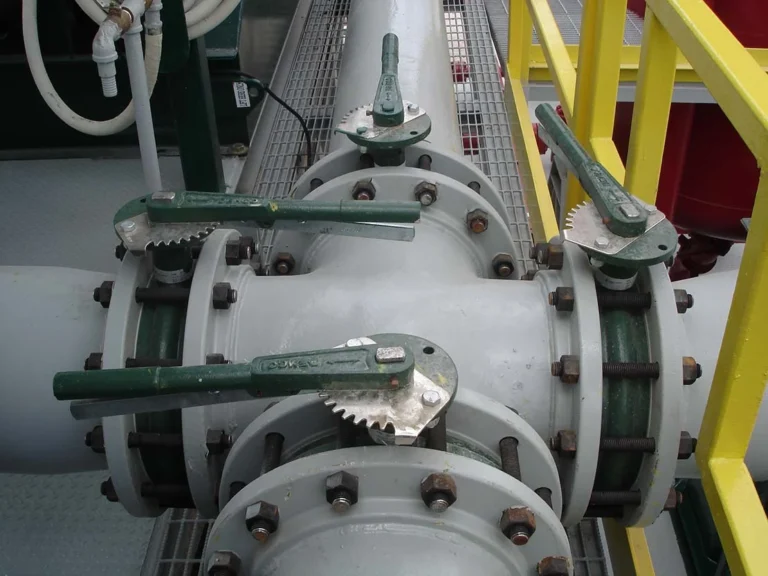

This type of butterfly valve has characteristics of higher pressure and temperature rating than that of the ordinary butterfly valves. These valves come in double-offset or triple-offset body design which means that there is considerably less friction when the valve is in operation and the seal is much more secure than on other types of valves. This design also increases the valve’s optimum performance in that it cannot leak no matter the pressure applied on it. The construction of high performance butterfly valves allows them to be used in industries which include oil and gas, chemical processing and power generation industries.

Another characteristic that the high performance butterfly valves possess is the flow characteristics. The unique design reduces the level of wear of the valve parts and in turn increases the lifespan of the valve and in effect reduces the level of maintenance that has to be conducted as a result. These benefits are most often promoted by high performance butterfly valve manufactures as proof of their valve’s ability in harsh conditions where standard valves cannot cope. If you use a high quality valve from a reliable China valve supplier, you can guarantee that the valve will function efficiently without many problems such as leakage and breakdowns.

Robustness, Reliability, and Economical Viability

One of the most essential features of high performance butterfly valves is the provision of impressive durability particularly when working under high pressure. These valves are made of materials that have the ability to cope with very high pressure and temperatures so that they can be very much reliable in their use. The double-offset or the triple-offset design of the valve ensures that contact between the valve disc and the seat is minimized in the valve thus reducing wear and tear which would be required frequently in other commonly used valves. This also increases the period of the valve but also ensures that the performance of the valve is maintained right from times when the valve has undergone many cycles of operation.

In conditions, when valve failures might result in significant losses or even result in dangerous situations, such as process enclosure, high performance butterfly valves are characterized by their high levels of reliability. When you use valves from the recognized China valve manufacturers, you can be assured they are well built and thus, there will be less need to replace them or carry out regular maintenance. The fact that these valves are much more physically robust than flap valves in the long term contributes to their much-reduced cost – less service and replacement, more reliable in terms of not completely failing.

The high performance butterfly valves combination of tough structure and efficiency in its working is able to provide economical solutions for high pressure applications. Due to such design, they can enable and disable the amount of fluid as required in any system and hence provide the best system efficiency. Consequently, as compared to other kinds of the valves that may generate pressure drops or that need more force to open, high performance butterfly valves feature low torque, and therefore, less energy expenditures in the case of the automated systems are typical for them. The efficiency of these valves make it possible that they might assist in maintaining the optimal performance of the system and at the same time reduce the energy consumption. Also, their adaptability and the relative simplicity of the installation and maintenance of the high performance butterfly valves also reflects in their cost effectiveness. In their original location, if purchased from a professional China valve manufacturer, these valves provide great value for money in terms of their performance at high pressure levels, suitable for industrial networks that require high pressure.

Versatility Across Various Industries

Butterfly valves are exceptionally rated for high performance and come in a variety of options which means they can solve a whole lot of problems in just about any industry or area of operation. These valves are applied in the oil and gas industry to regulate the flow of the crude oil, natural gas and other related products under conditions of high pressure. Such a sealing system can remain wetted and thus offer a strong seal in extreme conditions such as on offshore platforms and pipelines. In chemical processing industries, high performance butterfly valves allow the flow of aggressive chemicals and thus safe and efficient operations.

Another important industry that could not do without high performance butterfly valves is the power generation industry. These valves are utilized in steam systems, cooling water circuits and all other applications involving high pressures where certain and definite control of the fluids is compulsory for enhanced effectiveness and security. These valves can be used in water treatment plants, air condition systems, food processing and other industrial applications where their stability makes operations very efficient and safe.

Selection Of A Reputable China Valve Manufacturers

To purchase high performance butterfly valves in a high pressure system, one must be very careful in selecting a manufacturer and supplier from China. A reliable manufacturer of valves will follow the quality control measures and guarantee that the valves produced are satisfying the prescribed standard. This precision helps to deliver valves that may be of great service, highly resistant, safe and reliable in extremely sensitive processes.

When selecting the high performance butterfly valve suppliers, certain points to consider include the experience of the suppliers and the suppliers’ reputation as well as their current stock. A manufacturer who has a good experience in the production of valves should be in a position to assist the client to choose the most appropriate valve for the application. Furthermore, it would be possible for you to get the best technology in valves from a reputable China valve manufacturer since they will be using current technology to manufacture the right valves that will favor the high-pressure systems you will be using in your system.

Conclusion

Butterfly valves have a high working pressure rating and hence, have the following advantages for high pressure applications: They can stand exact pressures and temperatures and do not allow their fluids to leak or mix with other fluids which makes them suitable for fluids industries. If you go for a quality valve from the China valve manufacturer you shall be very sure of your system with very little failures. Purchasing high performance butterfly valves is a step that will help the company get away from the costly yearly maintenance and overhaul, to increase its operational efficiency and to improve overall safety.